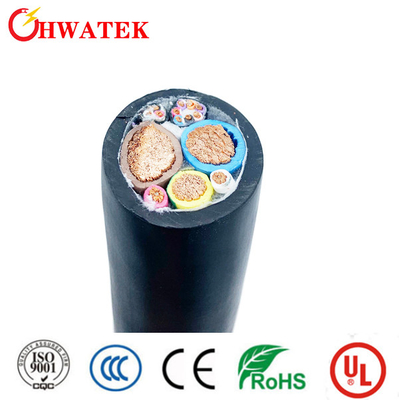

1000V Hv High Voltage EV Power Charger Multicore DC Electric Wire Cable

| SPECIFICATION |

CABLE NAME |

EV Cable |

| CABLE SPEC |

2C×80mm2+1C×25mm2+2C×4mm2+(3C×0.75mm2)(P2)+(7C×0.75mm2) |

| RoHS Compliant |

| Item |

A : 2C×80mm2 |

B : 1C×25mm2 |

C : 1C×4mm2 |

D:(3C×0.75mm2)(P2) |

E:(7C×0.75mm2) |

| CONDUCTOR |

Material |

Bared copper stranded |

| Size |

2580/0.20 ±0.008mm |

798/0.20 ±0.008mm |

224/0.15±0.008mm

+10/1#Tinsel+1000D Kevlar |

40/0.15±0.008mm+

10/0.19mmTinsel+200DKevlar |

40/0.15±0.008mm+

10/0.19mmTinsel+200D

Kevlar |

| O.D.(Ref.) |

12.40±0.25mm |

7.00±0.20mm |

2.70±0.15mm |

1.40±0.10mm |

1.40±0.10mm |

| INSULATION |

Material |

Thermoplastic(EF2585,85±3A) |

| Min. average thickness |

1.60mm |

1.20mm |

1.00mm |

0.50mm |

0.50mm |

| Min.thickness at any point |

1.34mm |

0.98mm |

0.80mm |

0.35mm |

0.35mm |

| O.D. |

15.60±0.40mm |

9.60±0.30mm |

4.70±0.20mm |

2.50±0.10mm |

2.50±0.10mm |

| CABLING-1 |

Filler |

/ |

Cotton |

Cotton |

| Material |

/ |

AL-mylar(facing out) |

Non-woven |

| BRAID |

Material |

/ |

Tinned copper |

/ |

| Size |

/ |

0.12mm,≥60% |

/ |

| In-JACKET |

Material |

/ |

TPE |

TPE |

| Min. average thickness |

/ |

0.60mm |

0.60mm |

| Min.thickness at any point |

/ |

0.42mm |

0.42mm |

| O.D. |

/ |

7.20±0.25mm |

9.70±0.25mm |

| CABLING |

Filler |

Strengthed PP rope |

| Material |

Non-woven(≥25% overing) |

| Assembly |

2C×80mm2+1C×25mm2+2C×4mm2+(3C×0.75mm2)(P2)+(7C×0.75mm2) |

| JACKET |

Material |

TPU |

| Min. average thickness |

2.80mm |

| Min.thickness at any point |

2.28mm |

| O.D. |

38.00+0.6/-1.00mm |

| ELECTRICAL CHARACTERISTICS |

| Rated voltage:DC 1000V |

| Rated temperature:Jacket -40~90℃ |

| Insulation -40~125℃ |

| Max. conductor resistance(20℃): |

| A:0.242Ω/km B:0.78Ω/km C:4.95Ω/km D&E:26Ω/km |

| Insulation Voltage withstand(Core A&B,10m): |

| AC 2.5kV/5min,leakage current ≤5mA |

| Completed cable Voltage withstand(Core A to A&B,10m): |

| AC 3.5kV/15min,leakage current ≤5mA |

| Min. Insulation resistance(20℃, Core A to A&B):500MΩ.km |

| PHYSICAL PROPERTIES |

| Tensile strength:≥20MPa |

High temperature pressure test:≤50% |

| Elongation:≥300% |

Heat shock test:No crack |

| Aged condition:110±1℃×168h |

Compatibility test:GB/T 33594 |

| Percent of original tensile strength:≤±30% |

Crush resistance test:GB/T 33594 |

| Percent of original elongation:≤±30% |

Curved around the test:GB/T 33594 |

| Flame test:GB/T 18380.12-2008 |

Min. Bend radius:6*OD |

| Artificial weathering test:GB/T 33594 |

Abrasion resistance:≥2000times |

| Low-temperature impact test :-40℃×16H,No crack |

Resistance against chemicals:GB/T 33594 |

| Chemical stress acid: N-Oxal-acid alkaline solution, N-sodium hydroxide solution:GB/T 33594 |

| Vehicle rolling:Requirements and test methods should be consistent with GB/T 20234.1-2015 7.21 |

Company Profiles

Founded in 2004 with 16 years of development, we Hwatek established our new plant Nantong Hwatek Wires & Cable Co., Ltd in 2020. Located in Nantong City, Jiangsu Province, our new plant covers 34,000 square meters with 100 million investment.

We are dedicating to R&D and produce various wires and cables like industrial control, communication instruments, medical control, green energy EV and special wires and cables etc. OEM & ODM is also available.

Our Nantong Plant has passed ISO9001, ISO14001, IATF16949, ISO13485 quality system certification. All the ranges of our wires and cables are CCC, UL, CUL, CE, CSA or ETL qualified. With the company principle ’Profession, Integrity, Eco Friendly and Win-win’, we are equipped with a comprehensive sales network to serve customers in various fields around the world.

Our Competence at

1. Produce Cables with Following Insulation & Jacket PVC, SR-PVC, XL-PVC(CL PVC), XLPE, FRPE, TPE, FEP Etc.

2. Produce Cables with Temperature Range from -40 to 200 Degree Temperature.

3. Produce Cables with Volatge Range from 30V to 1200V DC.

4. Flamability Rating - VW-1, FT1, FT2.

5. We have 300 Plus different UL Style approval from UL Authority.

6. QMS Certification- ISO9001-2015, IATF16949-2016, ISO13485-2016.

7. Product Certification -CCC, UL, CSA, ETL, CE.

8. We can support drop-in equivalent to any Brand of Cables and Custom made Cables.

Certificates

Production Progress

Shipping

FAQ

1.Q:What can you supply?

A: We do produce consumer electronics wires, hock up wires, industrial cables, robot cables, ev charging cables, new/green energy cables.

2.Q: What are the certificates do you get?

A: We have UL, CE, 3C, Dekra, CQC, TUV, Rohs, Reach, ETL certificates.

3.Q:Can we get samples before ordering?

A:Yes, we are willing to arrange samples for you.

4.Q: What's your lead time?

A: Normally we can finish you orders in 2-3 weeks, and 5-6 weeks in peak season.

5.Q. How can you guarantee the product quality?

A: Always a pre-production sample before mass production and final Inspection before shipment.

Major Customers

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!